What is a tempering valve?

A tempering valve is a type of valve used in hot water systems to precisely mix hot and cold water to a specific, safe temperature before it is delivered to outlets such as showers and taps. This device is essential in preventing scalding and ensuring that water is delivered at a consistent and comfortable temperature for everyday use.

In its most basic form, a hot water tempering valve consists of a

thermostatic element that is sensitive to temperature changes. It automatically adjusts the mix of hot and cold water to maintain a preset temperature. If the incoming water temperature fluctuates, the valve compensates by altering the ratio of hot to cold water. This ensures that the water exiting the valve remains at the desired temperature, regardless of variations in the supply system.

How does a tempering valve work?

A tempering valve operates by blending hot and cold water to deliver water at a safe, consistent temperature, and its mechanism is a fine example of simple yet effective engineering.

The valve has two inlets, one for hot water and one for cold water. Hot water typically comes from a heater at high temperatures, while cold water is supplied directly from the mains.

As hot and cold water enter the valve, they reach the thermostatic element. This element is sensitive to the temperature of the incoming water. The thermostatic element adjusts the proportion of hot and cold water allowed to pass through based on the temperature it detects. If the incoming hot water is too hot, the valve allows more cold water and less hot water to pass through, and vice versa.

The result is a consistent blend of hot and cold water that reaches a preset temperature, typically around 50 degrees Celsius. This temperature is generally safe for most domestic and commercial uses and significantly reduces the risk of scalding.

In case of a failure in the cold water supply, the thermostatic element in many tempering valves is designed to shut off the hot water flow. This safety feature prevents extremely hot water from reaching the outlet.

The tempering valve continuously adjusts the mix of hot and cold water to respond to any changes in the temperature or pressure of the incoming water, ensuring that the water temperature at the outlet remains constant and safe. This automatic adjustment is what makes tempering valves an essential component in modern plumbing systems, providing a balance between safety and comfort.

What is the difference between a tempering valve and a thermostatic mixing valve?

While a tempering valve might sound similar to a thermostatic mixing valve, there is a distinct difference between the two. The primary purpose of a tempering valve is to control the temperature of water, specifically to prevent scalding. It is often set to a factory-defined temperature suitable for general applications, like in a domestic water system.

On the other hand, a thermostatic mixing valve offers more precise control over the output temperature and is typically used in environments where specific temperature settings are required, such as in healthcare facilities or industrial applications. Thermostatic mixing valves often have the capability to shut off the water flow automatically in case of a failure in the cold water supply, providing an added layer of safety.

While both serve to blend hot and cold water to a safe temperature, the tempering valve is more about general safety and scald prevention, whereas the thermostatic mixing valve offers more precise temperature control and is suited for more specialised

commercial plumbing applications.

What temperature should a tempering valve be set at?

The recommended setting for tempering valves is generally determined by the balance between preventing scalding injuries and inhibiting bacterial growth, such as Legionella, in the water system.

The regulations for tempering valve temperature settings in South Australia are pretty specific. According to the South Australian government's plumbing standards, tempering valves in residential properties must be set to deliver hot water at a maximum temperature of 50 degrees Celsius at all sanitary fixtures used primarily for personal hygiene purposes, such as showers and hand basins. In public buildings the temperature should be no more than 45 degrees Celsius. This temperature is considered safe for preventing scalding injuries, which is especially important in households with children, the elderly, or individuals with disabilities who are more susceptible to burns.

The 50-degree Celsius limit strikes a balance between being high enough to minimise the risk of harmful bacterial growth in the water system and low enough to prevent scalding injuries. It's important to note that while 50 degrees Celsius is the maximum outlet temperature, the water stored in hot water systems is typically maintained at a higher temperature (around 60 degrees Celsius or higher) to further reduce the risk of Legionella bacteria proliferation.

It is important for property owners and plumbers in South Australia to follow the regulations when installing and adjusting tempering valves. Failure to comply can endanger safety and lead to legal and regulatory penalties. When dealing with hot water systems, it is always advisable to seek the assistance of a professional to prevent injuries.

Types and brands of tempering valves in Australia

In Australia, the market for tempering valves is diverse, offering a variety of types and brands tailored to meet the needs of different plumbing systems and user preferences.

- Standard Tempering Valves. These are the most common type, designed for general residential use. They are typically preset to a safe temperature of around 50 degrees Celsius and are used in household water systems to prevent scalding.

- Solar Compatible Tempering Valves. Specifically designed for solar hot water systems, these valves can handle the higher temperatures typically generated by solar collectors, ensuring safe water temperature output.

- High-Performance Tempering Valves. These are designed for commercial and industrial applications where water systems have higher demands. They offer greater durability and can handle higher flow rates and temperatures.

- Thermostatic Mixing Valves. Although not strictly tempering valves, they are often used in similar applications. They offer more precise temperature control and are typically used in healthcare facilities or industries where specific temperature settings are critical.

Notable Brands in Australia

- RMC (Reliance Worldwide Corporation). A well-known brand in Australia, RMC offers a range of high-quality tempering valves that are known for their reliability and compliance with Australian standards.

- Thermogroup. This brand is recognised for its solar-compatible tempering valves, which are specifically designed to work efficiently with solar hot water systems.

- Reece Plumbing. Offering a variety of tempering valves, Reece Plumbing is known for its broad range of products suitable for both residential and commercial applications.

- Bunnings Warehouse. While not a manufacturer, Bunnings Warehouse is a popular retailer in Australia that stocks a wide range of tempering valves from various reputable brands, making it a go-to for many consumers.

- Enware Australia. Known for their high-performance and durable products, Enware Australia's tempering valves are a common choice for commercial and industrial settings.

Each type and brand of tempering valve comes with its unique features and specifications, making them suitable for different applications. From standard residential use to more demanding commercial environments, the Australian market provides a comprehensive range of options to ensure safety and compliance with water temperature regulations. Whether one is looking for a valve for a new installation or replacing an existing one, these types and brands offer solutions tailored to a variety of needs and preferences.

How do I adjust the temperature on a tempering valve?

Adjusting the temperature on a tempering valve is a precise task that should be done carefully to ensure safety and compliance with local regulations. Here are the general steps and tips on how to safely adjust the temperature settings on a tempering valve.

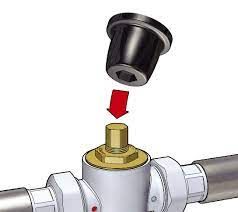

- Before starting, identify the type of tempering valve you have. Different models might have different mechanisms for adjustment.

- Gather necessary tools. Typically, you'll need a screwdriver or a specific tool provided by the valve manufacturer for adjustments.

- Turn off the water heater or boiler and allow the system to cool down to avoid any risk of scalding.

- Locate the temperature adjustment mechanism on the valve. This is often covered by a cap or a knob and may require a tool to open or adjust.

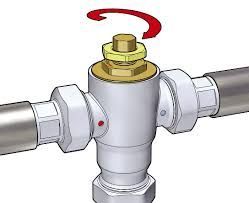

- Adjust the temperature setting in small increments. This is usually done by turning a screw or dial on the valve. Refer to the manufacturer's instructions for specific details, as the adjustment mechanism can vary between models.

- After making an adjustment, allow the water to run for a few minutes, and then check the temperature at a nearby tap. Use a thermometer to ensure accuracy.

- Repeat as necessary. If the temperature is not at the desired setting, repeat the adjustment process. It may take a few tries to get it right, as small adjustments can significantly change the output temperature.

- Once the desired temperature is achieved, ensure that any adjustment mechanisms are secured back in place to prevent accidental changes. Replace any covers or caps that were removed during the adjustment.

Safety Note

It is advisable to seek assistance from a professional plumber. Incorrect adjustments can lead to dangerously high temperatures and the risk of scalding. Remember, the goal of adjusting a tempering valve is to achieve a safe and consistent water temperature that complies with local safety standards. Therefore, precision and caution are key.

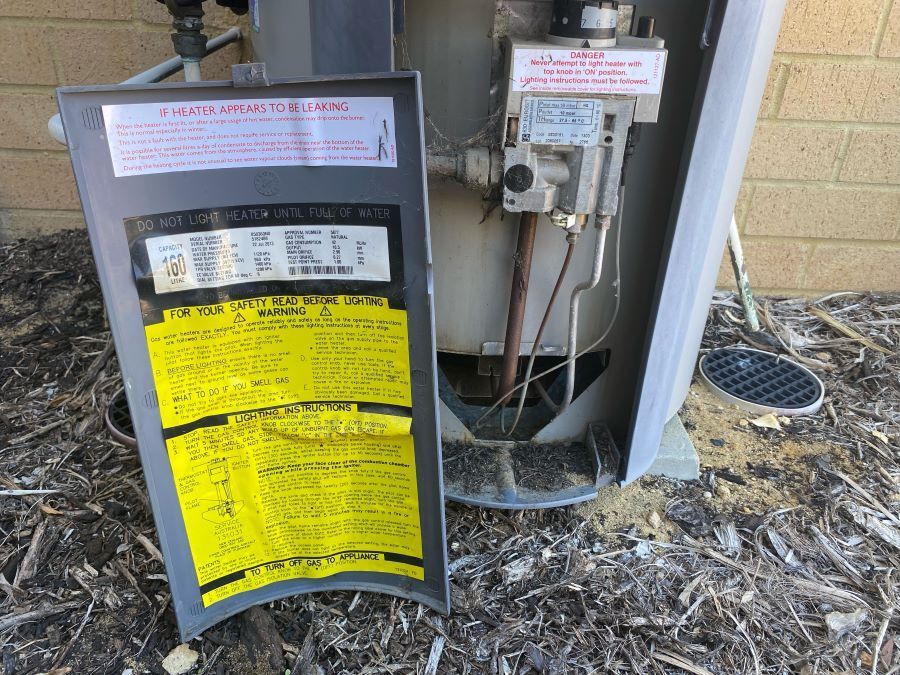

How often should a tempering valve be serviced?

Generally, it is recommended that tempering valves be serviced every 12 months. This annual maintenance ensures that the valve continues to operate correctly and deliver water at the correct temperature, preventing the risks associated with scalding or bacterial growth in the water system.

During a servicing session, a professional plumber typically conducts a thorough inspection and cleaning of the valve. This process includes checking for any signs of wear or damage, cleaning any debris or mineral buildup that may have accumulated, and replacing components like washers or seals if necessary. The plumber will also recalibrate the valve to ensure it delivers water at the correct temperature, in line with local regulations and safety standards.

Regular servicing of tempering valves is not just about maintaining functionality; it's also a safety requirement. Over time, valves can degrade or become less responsive, leading to fluctuations in water temperature. Annual maintenance helps to catch and rectify any such issues before they become serious problems. Contact local Adelaide Plumber such as Best Plumbing Maintenance.

In addition to professional servicing, it's also advisable for homeowners or building managers to perform regular visual inspections of the valves. Checking for leaks, corrosion, or any signs of malfunction can help identify issues that may require professional attention. Regular maintenance helps ensure that they function effectively, providing safe and consistent water temperatures in accordance with safety regulations and standards.

Can I install a tempering valve myself?

Installing a tempering valve is a task that requires specific plumbing knowledge and skills. For most people, it is advisable to hire a professional plumber for the installation of a tempering valve. Professional plumbers have the expertise and tools necessary to ensure that the valve is installed correctly and in compliance with local building codes and safety standards. This is particularly important as improper installation can cause not only functional issues but also legal and safety ramifications.

Additionally, in many regions, the installation of such safety devices is regulated by law, and DIY installation might not be compliant with these regulations. A professional installation typically comes with the assurance that the work meets the required standards, and it often includes a warranty for the work done.

What are the signs of a faulty tempering valve?

Common signs that may indicate a malfunction or issue with a tempering valve include inconsistent water temperature, no hot water at all, visible water leakage around the valve or unusual noises.

- Inconsistent water temperature. If you notice that the water temperature fluctuates widely or suddenly changes while in use, it could be a sign that the tempering valve is not functioning properly. A well-operating valve should consistently maintain a stable temperature.

- Water is too hot or too cold. If the water is consistently too hot or too cold, despite the correct settings, this could indicate a problem with the valve. It might not be mixing the hot and cold water correctly.

- No Hot Water. If there is a complete absence of hot water when the valve is supposed to mix hot and cold water, this might signal a malfunction within the valve, possibly due to a stuck or broken internal component.

- Water leakage. Visible leakage around the valve could indicate a problem. Leaks can be a sign of wear and tear, damaged seals, or other issues that might impair the valve's functionality.

- Physical damage or corrosion. Any visible signs of damage, such as cracks, corrosion, or wear on the valve, can affect its performance. Corrosion can especially be a concern, as it might lead to leaks or blockages within the valve.

- Unusual noises. Sounds like whistling, banging, or chattering coming from the valve are not normal. These noises could be a sign of internal problems, such as a loose part or issues with water pressure.

If you notice any of these signs, it's advisable to have a professional plumber inspect the valve. Contact

Best Plumbing Maintenance Adelaide. We can diagnose the issue and determine whether the valve needs repair or replacement. Regular maintenance can also help prevent these issues and ensure that your tempering valve operates efficiently and safely.